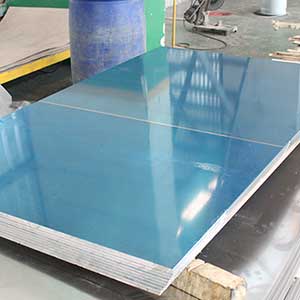

Marine Aluminium Grade

Marine aluminum alloy refers to a specific type of aluminum that is designed and manufactured to withstand harsh marine environments. This alloy is commonly used in the shipbuilding industry to construct various parts of a vessel.

Importance of Marine Aluminum Alloy in the Shipbuilding Industry

Marine aluminum alloy is an essential component of modern shipbuilding. It is used to build lightweight, durable, and corrosion-resistant ships that can withstand the harsh marine environment. This alloy is also crucial in improving the fuel efficiency of a ship and reducing its overall carbon footprint.

Marine Aluminum Alloy Properties

1.Corrosion Resistance

Marine grade aluminium is highly resistant to corrosion, even in saltwater environments. This property is essential for shipbuilding because it ensures that the vessel can withstand the corrosive effects of saltwater without suffering significant damage.

2. Lightweight and High Strength

Marine grade aluminium is both lightweight and strong, making it an ideal material for constructing large ships. The combination of these properties allows ships to be built with a higher payload capacity while still maintaining their structural integrity.

3. Weldability

Marine grade aluminium is highly weldable, allowing for easy assembly and repair of ship components. This property is crucial in ensuring that ships remain operational and functional throughout their lifespan.

4.Malleability

Marine grade aluminium is highly malleable, meaning it can be easily molded and shaped into various forms. This property allows shipbuilders to create complex shapes and designs, resulting in a more efficient and aesthetically pleasing vessel.

5.Durability

Marine grade aluminium is incredibly durable and can withstand harsh environmental conditions such as high winds, heavy rain, and extreme temperatures. This property ensures that ships built with this alloy can withstand the rigors of the marine environment and remain operational for many years.

What are the applications of Marine Aluminum Alloy?

Hull Construction

Marine grade aluminium is commonly used in hull construction because of its lightweight and high strength properties. The use of this alloy in hull construction results in a more fuel-efficient vessel and reduces the overall weight of the ship.

Decking and Superstructures

Marine grade aluminium is also used in the construction of ship decking and superstructures. This alloy’s lightweight property allows for the creation of larger and more complex structures without compromising the ship’s structural integrity.

Piping and Tanks

Marine grade aluminium is also used in the construction of piping and tanks on ships. The corrosion-resistant property of this alloy ensures that the piping and tanks remain functional throughout the ship’s lifespan.

Marine Equipment

Marine grade aluminium is also used in the construction of various marine equipment such as cranes, winches, and davits. This alloy’s lightweight property makes it an ideal material for constructing such equipment, ensuring that they are easy to operate and maneuver.

Best Aluminum Alloy For Marine

Marine grade aluminum 5083

5083 aluminum alloy is one of the most commonly used marine-grade alloys due to its excellent corrosion resistance and high strength. It is primarily used for hull construction, including oil tankers, bulk carriers, and container ships.

Marine grade aluminum 5086

5086 aluminum alloy is another popular marine-grade alloy known for its high strength and corrosion resistance. It is commonly used for hulls, superstructures, and piping systems of ships and boats.

Marine grade aluminum 6061

6061 aluminum alloy is a versatile alloy that is commonly used in marine applications. It is known for its high strength, excellent corrosion resistance, and good weldability. This alloy is commonly used for boat hulls, superstructures, and piping systems.

Marine grade aluminum 6063

6063 aluminum alloy is commonly used in marine applications due to its excellent corrosion resistance and good weldability. It is often used for deckings, handrails, and other non-structural components in boats and ships.

Marine Grade Aluminium vs Aluminium

Marine grade aluminum and regular aluminum differ in their composition, properties, and intended applications. Marine grade aluminum is a type of aluminum alloy that is specifically designed to withstand the harsh marine environment, including exposure to saltwater, corrosion, and other damaging elements. In contrast, regular aluminum can be used in a wide range of applications, but it may not be suitable for use in marine environments.

The primary difference between marine grade aluminum and regular aluminum is the alloying elements used to create them. Marine grade aluminum typically contains magnesium, which improves its strength and corrosion resistance. Regular aluminum, on the other hand, usually contains other elements such as copper, zinc, or silicon, which may not offer the same level of protection against corrosion in marine environments.

In summary, marine grade aluminum offers superior corrosion resistance and durability compared to regular aluminum, making it ideal for use in marine environments. However, it is generally more expensive than regular aluminum due to its specialized composition and properties. Ultimately, the choice between marine grade aluminum and regular aluminum depends on the specific application and environment in which it will be used.