Aluminum Circle Introduction:

Lomi Aluminum can provide 1 series 3 series 5 series 8 series aluminum discs, which are exported to all over the world, and has rich export experience. We have a lot of experience in exporting to countries all over the world. If you do not know the specific alloy you need, you can ask us for advice.

| 1 series | O H*2 H*4 H*6 H18 H111 H112 | 1050 | 1. Aluminum content: 99%, excellent formability 2. High reflectivity 3. Stable surface anodizing performance |

1. general cookware: post-treatment: sanding, sandblasting, extruded lids; aluminum pots and pans. 2. Lighting accessories: downlights, laminated lamps, lampshades for street lamps, etc. 3. Indicator signs and construction materials: traffic signs, curtain walls,ceilings |

| 1060 | ||||

| 1070 | ||||

| 1100 | ||||

| 3 series | 3003 | 1. Good formability 2. High elongation, can be used for deep drawing process 3. Smooth surface and high reflectivity |

1. Advanced cookware: post-treatment: anodizing, enamel, spraying, deep drawing, etc.; non-stick cookware; pressure cooker; 2. Lighting accessories: downlights, laminated lamps, lampshades for street lamps, etc. 3. indication signs and construction materials: traffic signs, curtain walls, ceilings |

|

| 3004 | ||||

| 3005 | ||||

| 3105 | ||||

| 5 series | 5052 | 1. Low density of material, light weight of finished product 2. High tensile strength and elongation, good fatigue strength 3. Higher grain grade and good surface finish |

1. Aluminum non-stick pots, pans, soup pots, frying pans, teapots, pressure cookers | |

| 5754 | ||||

| 5083 | ||||

| 8 series | 8011 | 1. Good anodizing effect 2. Stable performance and high surface quality. |

1.Anodized cookware |

Chemical Composition (WT.%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | – | – | 0.05 | 0.03 |

| 1060 | 0.250 | 0.350 | 0.050 | 0.030 | 0.030.- | – | 0.050 | 0.030 | 99.6 |

| 1070 | 0.200 | 0.250 | 0.040 | 0.030 | 0.030 | – | 0.040 | 0.030 | 99.7 |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.050 | – | – | 0.100 | – | 99.0 | |

| 3003 | 0.600 | 0.700 | 0.05-0.20 | 1.0-1.5 | – | – | 0.100 | – | remains |

| 5052 | 0.250 | 0.400 | 0.100 | 0.100 | 2.2-2.8 | 0.15-0.35 | 0.100 | – | remains |

| 8011 | 0.5-0.9 | 0.6-1.0 | 0.100 | 0.200 | 0.050 | 0.050 | 0.100 | 0.080 | remains |

Video:

Aluminum Circle Features:

High formability

Strong mechanical properties

Good reflectivity

Good elongation and tensile strength

High strength, durability and corrosion resistance

Suitable for gas, hydrogen, resistance and brazing welding

Easy to undertake various pressure processing and extension or bending

Good deep drawing, good plasticity, good electrical conductivity, good processability

Can be glazed, covered with PTFE (or other), anodized

Bright or polished surface (customizable), clean, flat, free of integrity, oil, dents, inclusions, scratches, oxidative discoloration, fractures, corrosion, roll marks, dirt streaks and other defects that would interfere with use’

Aluminum Circle Applications:

Deep drawing cookers, spinning cookers, kitchen utensils, pizza pans, electric Fryers, baking pans, road signs, building materials, insulating materials, traffic signs

Aluminum Non-Stick Pans, Pot Bottoms, Soup Pots, Frying Pans, Teapots, Pressure Cookers, Pizza Pans, Rice Cookers Restaurant Cookers, Coffee Makers

Recessed Lighting, High Bay Industrial Lighting, Pressure Lighting, Traffic Light Reflectors, Sports Lighting

1060 O , H12 2mm — 3mm for frying pans, pizza pans, electric frying pans

3003 O , 2mm — 4mm for pressure cookers, rice cookers

1100 O , 0.7mm — 2mm for Stock Pots

1100 H14 For route signage, highway signs, school signs, rail and light rail signs, bicycle signs, recreational and cultural interest signs, regulatory traffic signs, warning traffic signs, guide signs

Common aluminum ring 1100 O 0.5 – 1.5mm Suitable for plain aluminum lampshade Performance advantage: Suitable for bare finish or common finish.

Anodized high quality aluminum circle 1100 O 0.5–1.5mm Suitable for anodized aluminum lampshade

Performance advantages: deep-drawn aluminum rounds of good quality, can maintain a semi-mirror finish after bright dipping and anodizing, with a minimum total reflectivity of 65%.

Coated aluminum ring 1100 O 0.5 – 1.5mm Coated aluminum lampshade Performance advantages: good painting surface and deep drawing quality.

Shipping and Packing Information:

1. Cover the fumigation chapter.

2. Place 20 packs of desiccant per carton.

3. Galvanized steel strip, coated cardboard package to prevent rust.

4. Pine wood bottom bracket is supported by glued bottom plate to maintain the flatness of the aluminum plate.

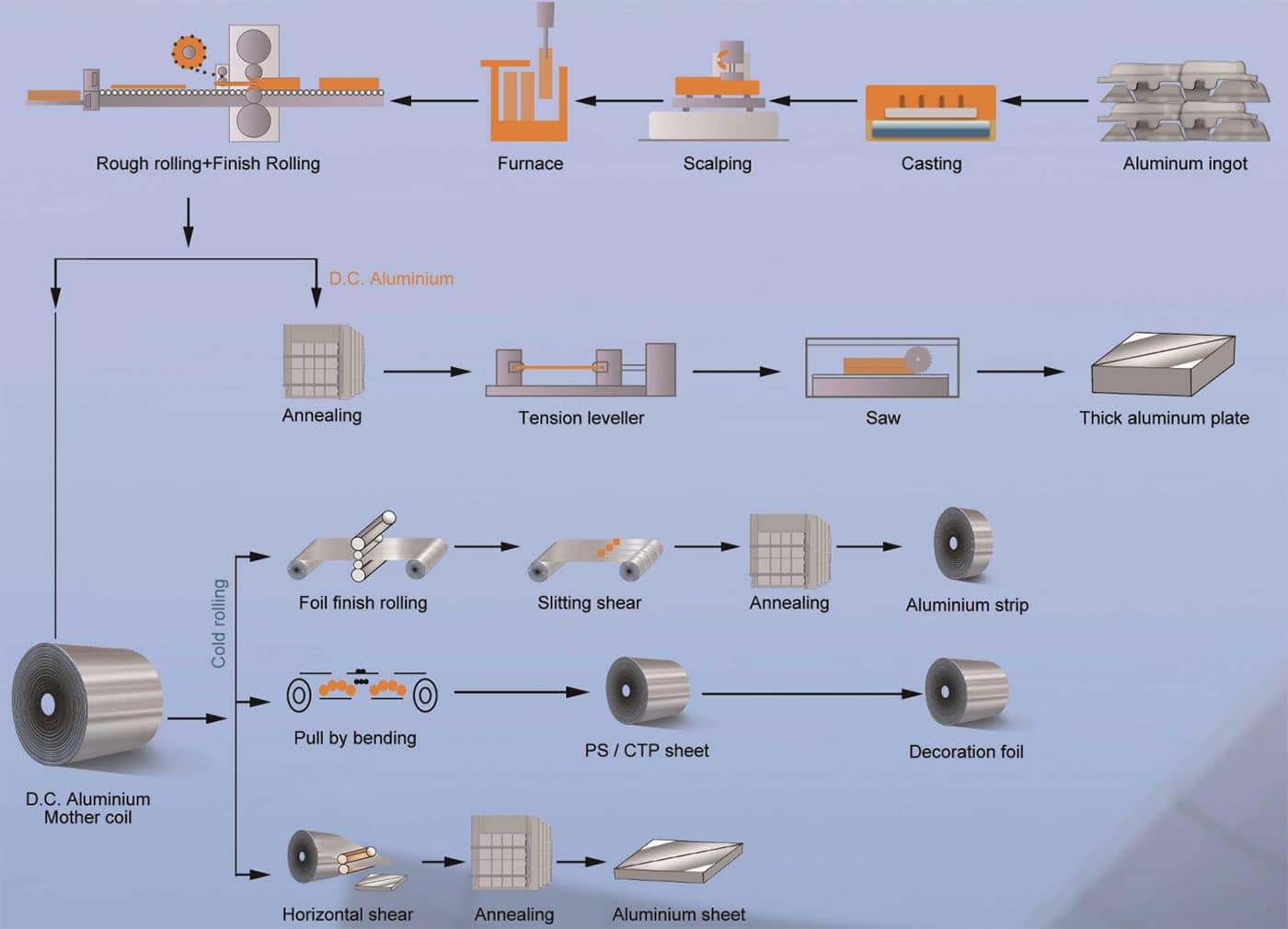

Product line:

Product Catalogue:

| Products | Alloy No. | Temper | Thickness(mm) | Width(mm) |

|---|---|---|---|---|

| 1000series | 1050/1060/1100/1235/1200/1145 | All Tempers | 0.2-6 | Under2200 |

| 3000series | 3003/3105 | All Tempers | 0.2-6 | Under2200 |

| 5000series | 5005/5052/5083/5086/5182/5754/5454/5A06/5A05/5251 | All Tempers | 0.2-6 | Under2200 |

| 6000series | 6061/6082/6063 | F/TX | 0.2-6 | Under2200 |

| 7000series | 7075/7050 | F/TX | 0.2-6 | Under2200 |

| 8000series | 8011 | All Tempers | 0.006-6 | Under2200 |

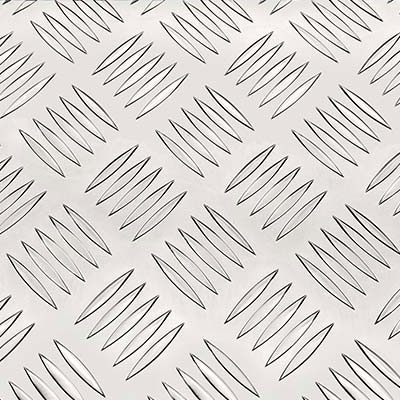

Types of Checkered Plates:

Color Coating Type:

Q: How long can I receive my goods?

A: It depends on the products you ordered. Generally, it needs 30-40 days.If products is stock , about 7-10days can delivery after received deposit.We have 3200 workers to manufacture aluminium products. We have complete production lines for meeting your needs of products quality and production speed to make sure that our products can get to you faster.

Q: What are your payment methods?

A: TT or 100% irrevocable L/C at sight.

Q: What is your MOQ?

A: Our MOQ is based on the alloy number and the thickness and width of the aluminum sheet.1000 series MOQ 5tons.

Q: How do you ship the goods and how long does it take to arrive ?

A : We usually ship by DHL , UPS , Fedex or TNT for sample. It usually takes 3-5 days to arrive . Seashipping for mass products.

Q: Are your aluminium products quality reliable?

A : We apply professional and advanced equipment for processing aluminium products. These equipment are top-class at home and abroad. What’s more, our factory has complete equipment configurations for fine machining. And we have precise equipment for testing products quality. Thus, the quality of end products can be promised.