1.As long as your demand reaches the MOQ, free A4 samples are free shipping

2.Our products have this high cost performance, you can consult us for samples and compare them with other suppliers,sure to make you feel good value for money

3.We can recommend suitable aluminum plate and temper for you according to your needs

4.We have 20 years of experience in exporting and manufacturing aluminum sheets, and we can definitely meet your requirements, whether it is price, delivery time, quality and service, etc.Welcome your inquiry

Product Catalogue:

| Products | Alloy No. | Temper | Thickness(mm) | Width(mm) |

| 1000series | 1050/1060/1100/1235/1200/1145 | All Tempers | 0.2-6 | Under2200 |

| 3000series | 3003/3105 | All Tempers | 0.2-6 | Under2200 |

| 5000series | 5005/5052/5083/5086/5182/5754/5454/5A06/5A05/5251 | All Tempers | 0.2-6 | Under2200 |

| 6000series | 6061/6082/6063 | F/TX | 0.2-6 | Under2200 |

| 7000series | 7075/7050 | F/TX | 0.2-6 | Under2200 |

| 8000series | 8011 | All Tempers | 0.006-6 | Under2200 |

1. Standard: ASTM/DIN/GB/SUS

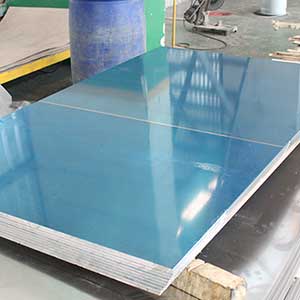

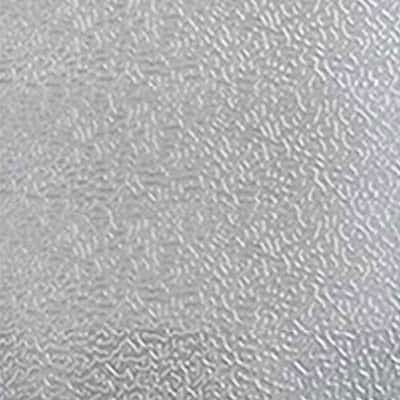

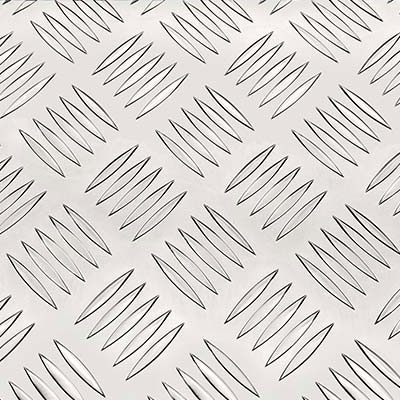

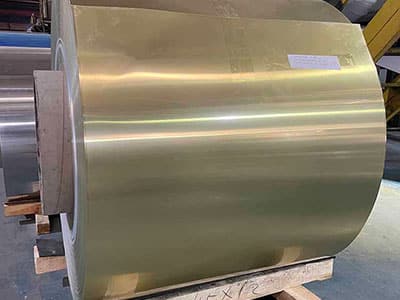

2. Surface: Mill, Bright,Polished,Hairline, Embossed,etching

3.Temper: O, H12, H22, H32, H14, H24, H34, H16, H26, H36, H18, H28, H38, H19, H25, H27,H111, H112,H241, H332, etc.;T4,T6,T651 Etc

4.Thickness: 0.02mm ~ 300mm

5. Width: 10mm ~ 2200mm

Can be processed:

Types of Checkered Plates

Color Coating Type

Shipping and Packing Information:

1. Cover the fumigation chapter.

2. Place 20 packs of desiccant per carton.

3. Galvanized steel strip, coated cardboard package to prevent rust.

4. Pine wood bottom bracket is supported by glued bottom plate to maintain the flatness of the aluminum plate.

Why Choose Us?

Our service

|

Annual capacity

|

DNV,SGS, BV, CE, COC, AI

|

Free samples

|

Within 24h

|

Perfect service

|

|

600000 Tons

|

Available

|

A4 Size

|

Respone Time

|

Professional Teams

|

|

1. ISO Verified Outstanding Manufacturer

2. The third party inspection: SGS, BV, CE, COC, AI and other 3. Flexible Payment : T/T, LC, O/A, CAD, DAP , KUNLUN Bank 4. Sufficient Stock 5. Quick Delivery Time, Long time price validity 6. Tracking picture of transport : production, Loading and reinforcement loading Pictures 7. Rich experience Professioal Sale Team |

1. Quality Guarantee after Receiving the Goods: Offer money return or Ship new products for free if any problems happen 2.

Technical Guidance for further Processing |

|||

Quality Assurance

1.All qualified examined by construction materials by the Satate Quality Supervision Center and we have got ISO9001:2008 and CCS,so we can adapt to meet customer’s high requirement of quality.we garantee that all coils/sheets below 3mm will pass through the tension leveller.(free)

2.Raw materials: We carefully select high-quality raw materials and subject them to purity, strength, and durability tests to ensure their quality meets our standards.

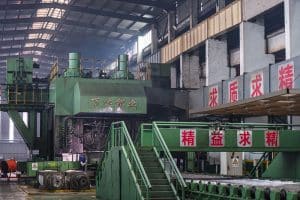

3.Manufacturing process: We employ advanced production technology and equipment and implement rigorous quality control measures at every stage of the manufacturing process to ensure that our aluminum plates are of the highest quality.

4.Performance: Our aluminum plates possess outstanding properties, including high strength, excellent corrosion resistance, and exceptional formability. They are suitable for various applications and can fulfill the requirements of a wide range of industries.

5.Testing and certification: Our aluminum plates undergo rigorous testing to ensure that they meet international quality standards, and they are certified accordingly. We provide customers with comprehensive test reports and certifications to guarantee the quality of our products and give them peace of mind.

Processing Equipment

FAQ

Q: How long can I receive my goods?

A: It depends on the products you ordered. Generally, it needs 30-40 days.If products is stock , about 7-10days can delivery after received deposit.

We have 3200 workers to manufacture aluminium products. We have complete production lines for meeting your needs of products quality and production speed to make sure that our products can get to you faster.

Q: What are your payment methods?

A: TT or 100% irrevocable L/C at sight.

Q: What is your MOQ?

A: Our MOQ is based on the alloy number and the thickness and width of the aluminum sheet.1000 series MOQ 5tons.

Q: How do you ship the goods and how long does it take to arrive ?

A : We usually ship by DHL , UPS , Fedex or TNT for sample. It usually takes 3-5 days to arrive . Seashipping for mass products.

Q: Are your aluminium products quality reliable?

A : We apply professional and advanced equipment for processing aluminium products. These equipment are top-class at home and abroad. What’s more, our factory has complete equipment configurations for fine machining. And we have precise equipment for testing products quality. Thus, the quality of end products can be promised.

What is 3004 aluminum Sheet?

3004 Aluminum sheet is an aluminum-manganese alloy belonging to the 3000 series of aluminum alloys. It has good formability, weldability, and corrosion resistance, and is a widely used material in various fields.

Chemical Composition

| Al | Mg | Si | Fe | Cu | Zn | Mn | Remainder |

|---|---|---|---|---|---|---|---|

| 95.6 to 98.2% | 0.8 to 1.3% | 0.3% max | 0.7% max | 0.25% max | 0.25% max | 1.0 to 1.5% | 0.15% max |

Physical Properties

| Density | 2.72 g/cm³ or 0.098 lb/in³ |

| Melting Point | around 610°C or 1130°F. |

| Thermal Conductivity | around 121 W/m-K or 70 Btu/ft-hr-°F |

| Electrical Conductivity | around 34.7 MS/m or 114 ft/mΩ |

| Coefficient of Thermal Expansion | 24.2 µm/m-K or 13.4 µin/in-°F |

| Specific Heat Capacity | around 903 J/kg-K or 0.216 Btu/lb-°F |

| Young’s Modulus | around 70 GPa or 10 Msi |

Mechanical Properties

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 215 MPa | 31183 psi |

| Yield strength | 170 MPa | 24656 psi |

| Shear strength | 115 MPa | 16680 psi |

| Fatigue strength | 105 MPa | 15229 psi |

| Elastic modulus | 70-80 GPa | 10153-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

| Elongation | 10% | 10% |

| Hardness | 52 | 52 |

3004 aluminum properties

Strength:

Aluminum 3004 has moderate strength, which makes it suitable for use in applications that require a combination of strength and formability.

Formability:

This alloy has excellent formability, which means it can be easily shaped into a variety of forms and sizes.

Corrosion resistance:

Aluminum 3004 has good corrosion resistance, which makes it ideal for use in environments where it may be exposed to moisture or other corrosive substances.

Weldability:

This alloy has good weldability, which means it can be easily welded using various welding techniques.

Surface finish:

Aluminum 3004 has a smooth surface finish, which makes it ideal for applications that require a high-quality finish, such as packaging and printing.

Thermal conductivity:

This alloy has good thermal conductivity, which means it can transfer heat quickly and efficiently.

Electrical conductivity:

Aluminum 3004 has good electrical conductivity, which makes it suitable for use in electrical applications.

Lightweight:

Aluminum 3004 is a lightweight material, which makes it ideal for use in applications where weight is a critical factor, such as transportation.

Machinability:

This alloy has good machinability, which means it can be easily machined into various shapes and sizes.

Anodizing:

Aluminum 3004 can be easily anodized to improve its surface hardness, wear resistance, and corrosion resistance.

Paintability:

This alloy has excellent paintability, which means it can be easily painted or coated with various finishes to enhance its appearance and protection against corrosion.

Non-toxic:

Aluminum 3004 is a non-toxic material, which makes it ideal for use in food packaging and other applications where hygiene is critical.

Recyclable:

Aluminum 3004 is a highly recyclable material, which makes it an environmentally friendly choice for many applications.

Common temper states for 3004 aluminum sheet

H12: This is a strain-hardened and partially annealed temper state. It has low strength and high formability.

H14: This is a strain-hardened and partially annealed temper state. It has medium strength and good formability.

H16: This is a strain-hardened and partially annealed temper state. It has high strength and moderate formability.

H18: This is a strain-hardened and fully annealed temper state. It has the highest strength but lower formability than the other temper states.

Other Designations

AA3004: This is the Aluminum Association (AA) designation for aluminum alloy 3004.

EN AW-3004: This is the European designation for aluminum alloy 3004, as defined by the European Committee for Standardization (CEN).

AlMn1Mg1: This is the German designation for aluminum alloy 3004, as defined by the German Institute for Standardization (DIN).

A93004: This is another designation that is sometimes used for aluminum alloy 3004.

UNS A93004: This is the Unified Numbering System (UNS) designation for aluminum alloy 3004, which is a system used to identify metals and alloys in North America.

ISO AlMn1Mg1: This is the International Organization for Standardization (ISO) designation for aluminum alloy 3004.

3004 Aluminum Alloy Standard

ASTM B209: This is the standard specification for aluminum and aluminum-alloy sheet and plate, which covers 3004 aluminum alloy in various temper conditions.

EN 573-3: This European standard specifies the chemical composition and mechanical properties of aluminum and aluminum alloys, including 3004.

JIS H4000: This Japanese Industrial Standard specifies the properties and dimensions of aluminum and aluminum alloy sheets and plates, including 3004.

GB/T 3880: This Chinese standard specifies the technical requirements for aluminum and aluminum alloy sheets and plates, including 3004.

Applications

Beverage cans: 3004 aluminum alloy is often used to manufacture the tops and bottoms of beverage cans due to its good formability and resistance to corrosion.

Heat exchangers: The excellent corrosion resistance of 3004 aluminum alloy makes it a suitable material for heat exchangers in various industries such as automotive, HVAC, and refrigeration.

Chemical equipment: The corrosion resistance and weldability of 3004 aluminum alloy make it a suitable material for chemical equipment such as storage tanks and pipelines.

Building and construction: Aluminum alloy 3004 is used in the construction industry for roofing, siding, and gutters due to its corrosion resistance and durability.

Electrical and electronics: The good electrical conductivity of 3004 aluminum alloy makes it a suitable material for electrical and electronic applications such as heat sinks and power transmission lines.

Why Choose Longmi Aluminum?

If you are an aluminum sheet factory, your success largely depends on your supply chain and partners. Choosing the right aluminum sheet supplier is crucial because they will affect your production process, product quality, and customer satisfaction. Here are some reasons why you may choose us:

Quality assurance: We have strict quality control standards and processes to ensure that our aluminum sheets meet international standards and customer requirements. Our aluminum sheets are made from high-quality raw materials and undergo multiple inspections to ensure that each product meets your quality requirements.

Experienced professional team: We have an experienced, technically skilled, and customer-focused professional team that can provide the best solutions and services to ensure your needs are met.

Comprehensive range of products: Our products cover various aluminum sheet specifications, materials, and shapes, to meet your needs in different fields and applications.

Reliable supply chain management: Our supply chain management is excellent, with strict procurement and production plans to ensure timely supply and delivery while reducing inventory costs and risks.

Competitive prices: We are committed to providing the most competitive prices while ensuring product quality and service reliability.

If you choose us as your aluminum sheet supplier, you can get high-quality products, professional technical support, and excellent customer service, while also improving your production efficiency and product quality. We believe that we will be your reliable partner and achieve mutual success together.

E-mail: lomialuminum@gmail.com

Tel Whatsapp: +86 19339942739