As the world’s population continues to grow, so does the demand for new construction projects. With this demand comes the need for durable and reliable materials that can withstand the rigors of modern construction. One such material that has gained popularity in recent years is aluminum plate. In this article, we will explore the benefits of using aluminum plate as a structural component in construction and how it is shaping the future of the industry.

Aluminum plate is a lightweight material that is often used in the aerospace and automotive industries due to its high strength-to-weight ratio. This same property makes it an ideal material for the construction industry, where weight reduction is a primary concern. By using aluminum plate as a structural component, builders can reduce the weight of their buildings without sacrificing strength or durability.

Another advantage of using aluminum plate in construction is its corrosion resistance. Unlike steel, which can rust and degrade over time, aluminum plate is highly resistant to corrosion. This makes it an excellent choice for buildings located in coastal areas or other environments where corrosion is a concern.

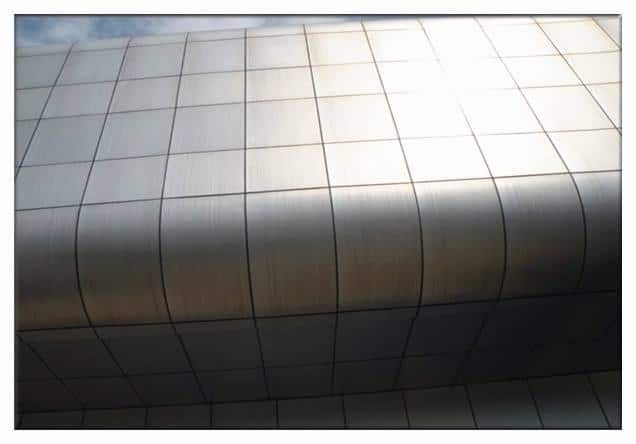

In addition to its strength and corrosion resistance, aluminum plate is also highly customizable. It can be cut and shaped to fit virtually any design, making it a versatile material for architects and builders. This flexibility allows for unique and creative designs that would not be possible with other materials.

One area where aluminum plate is making a significant impact in the construction industry is in the development of sustainable buildings. Aluminum is a highly recyclable material, which means that it can be reused again and again without losing its properties. This makes it an eco-friendly choice for builders who are looking to reduce their environmental impact.

The use of aluminum plate in construction is not without its challenges, however. One of the main concerns is the cost of the material. Aluminum is generally more expensive than other structural materials such as steel or concrete. However, many builders are starting to see the long-term benefits of using aluminum, such as reduced maintenance costs and increased energy efficiency.

Another challenge is the need for specialized equipment and expertise to work with the material. Aluminum plate requires different tools and techniques than other materials, which can add to the cost of construction. However, with the growing popularity of aluminum in construction, more and more builders are investing in the equipment and training necessary to work with the material.

Despite these challenges, the future of construction looks bright for aluminum plate. With its unique properties and versatility, it is sure to play an increasingly important role in the industry in the coming years. As builders continue to seek out sustainable and cost-effective construction solutions, aluminum plate is poised to become a go-to material for structural components.

In conclusion, aluminum plate is a lightweight, durable, and customizable material that is well-suited for use in the construction industry. Its unique properties make it an ideal choice for builders who are looking to reduce weight, increase durability, and create sustainable buildings. While there are challenges associated with working with aluminum plate, the benefits far outweigh the costs. As the construction industry continues to evolve, we can expect to see more and more builders turning to aluminum plate as a structural component.