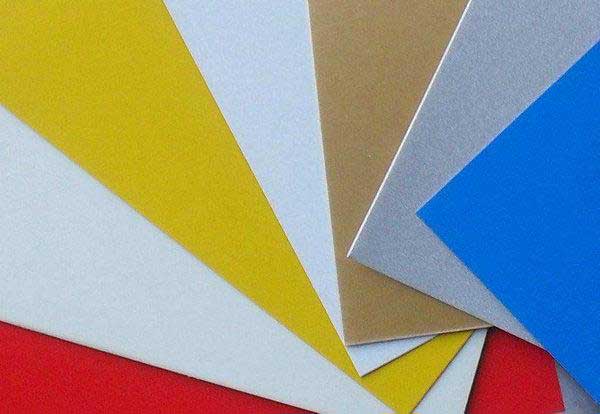

Types of colored aluminum sheets include:

- Coated aluminum sheet: Aluminum sheet treated with paint or resin coating on the surface, with good corrosion resistance, wear resistance and aesthetics. Common coating colors include white, black, gray, red, blue, etc.

- Fluorocarbon coated aluminum sheet: Aluminum sheet treated with fluorocarbon resin coating on the surface, with good weather resistance and pollution resistance, usually used for outdoor building curtain walls, signs, ceilings, etc.

- Color strip aluminum sheet: Aluminum sheet treated with coating and then divided into multiple narrow strips by machine to form a decorative aluminum sheet with multiple colors and stripes.

- Powder coated aluminum sheet: Aluminum sheet treated with powder electrostatic coating on the surface, with wear resistance, corrosion resistance and weather resistance. Common colors include metal color, black, white, gray, red, blue, etc.

- Wood grain color coated aluminum sheet: Aluminum sheet treated with imitation wood grain paper or film adhesive on the surface, with imitation wood grain effect, often used for indoor decoration.

- Tempered color coated aluminum sheet: Aluminum sheet treated with tempered glass coating on the surface, with good scratch resistance, wear resistance and sun protection performance, often used for building curtain walls, ceilings, etc.

- Sandblasted color coated aluminum sheet: Aluminum sheet treated with sandblasting and coating on the surface, with a matte texture and multiple colors to choose from, often used for indoor decoration and furniture manufacturing.

Do you know the differences between these coated aluminum sheets?

The differences between them are as follows:

- Fluorocarbon coated aluminum sheets have high performance in UV resistance, weather resistance, pollution resistance, adhesion, etc., and are suitable for high-end fields such as outdoor building curtain walls, with relatively high prices.

- Powder coated aluminum sheets have excellent weather resistance, corrosion resistance, plasticity, and decoration, and are commonly used in indoor decoration and furniture making, with relatively low prices.

- Color strip aluminum sheets are usually used in indoor decoration, furniture making, and other fields, with relatively low prices.

- Wood grain color coated aluminum sheets, tempered color coated aluminum sheets, and sandblasted color coated aluminum sheets have more realistic appearance effects and can perfectly simulate the texture and texture of natural materials, with relatively high prices.

- Tempered color coated aluminum sheets have high hardness, wear resistance, impact resistance, etc., and are commonly used in indoor and outdoor decoration and building curtain walls that require high safety.

- Sandblasted color coated aluminum sheets have a rough surface texture and are commonly used in indoor and outdoor decoration and building curtain walls that require an artistic appearance.

Common points:

- They are all made by coating different types of coatings on the surface of aluminum sheets.

- They can all be customized according to customer requirements, and can be made into aluminum sheets of different colors, shapes, and specifications.

- They all have good weather resistance and corrosion resistance, and can be used in indoor and outdoor decoration, building curtain walls, and other fields.

Application:

Building curtain walls: Color coated aluminum sheets can be made into various patterns, designs, and shapes of curtain wall panels for building decoration and protection.

Interior decoration: Color coated aluminum sheets can be made into various patterns, colors, and shapes of ceiling, wall, and floor panels for interior decoration and beautification.

Appliance manufacturing: Color coated aluminum sheets can be made into various appliance shells and panels, such as refrigerator, washing machine, microwave oven, rice cooker, etc., for beautification and protection.

Automotive manufacturing: Color coated aluminum sheets can be made into automotive shells and interior panels, such as roof, door, dashboard, door panel, etc., for beautification and protection.

Electronics manufacturing: Color coated aluminum sheets can be made into various electronic product shells and panels, such as mobile phone, tablet computer, television, audio, etc., for beautification and protection.

Packaging material manufacturing: Color coated aluminum sheets can be made into various packaging boxes, bottle caps, and food packaging bags, etc., for protection and decoration.

Aerospace field: Color coated aluminum sheets can be made into aerospace shell and structural components, such as aircraft fuselage, satellite shell, etc.

Other areas: Color coated aluminum sheets can also be used for making billboards, signs, railway train shells, ship shells, power cable protection materials, etc.

In summary, color coated aluminum sheets have wide applications in various industries and fields, and their good performance and attractive appearance make them an ideal choice for decorative and protective materials.

We can supply the base material of anodized aluminum, and various series of base materials are available. IF YOU NEED, CONTACT US PLEASE!

Contact Us!

E-mail: lomialuminum@gmail.com

Tel Whatsapp: +86 19339942739

Click our website: https://www.lomialuminium.com/aluminum-sheet-price/