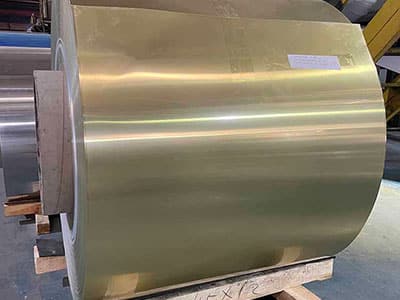

6061 Aluminum Coil Introduction:

6061 aluminum coil is another form of 6061 aluminum alloy. The main alloying elements contained in 6061 aluminum alloy are magnesium and silicon. It was originally called “alloy 61S”, which is a precipitation hardening aluminum alloy, commonly known as aviation-grade aluminum alloy. The common tempering states are 6061-T6 and 6061-T651. Among them, the T651 alloy is formed on the basis of the T6 state and is formed after eliminating the internal stress, which is more suitable for forming.

6061 Aluminum Coil Feature:

Excellent processability, excellent welding characteristics, electroplating and thermoplasticity.

High strength, high hardness, no deformation after processing, dense material without defects.

Easy to polish, easy to color, good anodizing effect.

Strong corrosion resistance, good toughness, very smooth surface, good usability.

Environmentally friendly and pollution-free, can be recycled

6061 Aluminum Coil Applications:

Representative applications include aerospace fixtures, electrical fixtures, and communications.

It is also widely used in automated mechanical parts, precision machining, mold manufacturing, electronic and precision instruments, SMT and PC board solder carriers, etc.

Trucks, towers, ships, pipelines and other equipment requiring strength, weldability and corrosion resistance

Aircraft parts, camera lenses, couplers, marine accessories and hardware, electronic accessories and connectors, decorative or various hardware, hinge heads, magnetic heads, brake pistons.

Hydraulic pistons, electrical accessories, valves and valve parts.

Worm Gears, Electrical Connectors, Electrical Accessories, Marine Accessories and Hardware, Marine Components

Truck bodies and frames Screw machine accessories Coated aluminium tiles Yacht construction including small utility boats.

Wings and fuselage, more common in homemade aircraft than commercial or military aircraft

Auto parts, such as the chassis of the Audi A8.

It enjoys a good reputation in the fields of mobile phone case materials, car hubs, trolley cases, and 3C products.

Shipping and Packing Information:

1. Cover the fumigation chapter.

2. Place 20 packs of desiccant per carton.

3. Galvanized steel strip, coated cardboard package to prevent rust.

4. Pine wood bottom bracket is supported by glued bottom plate to maintain the flatness of the aluminum plate.

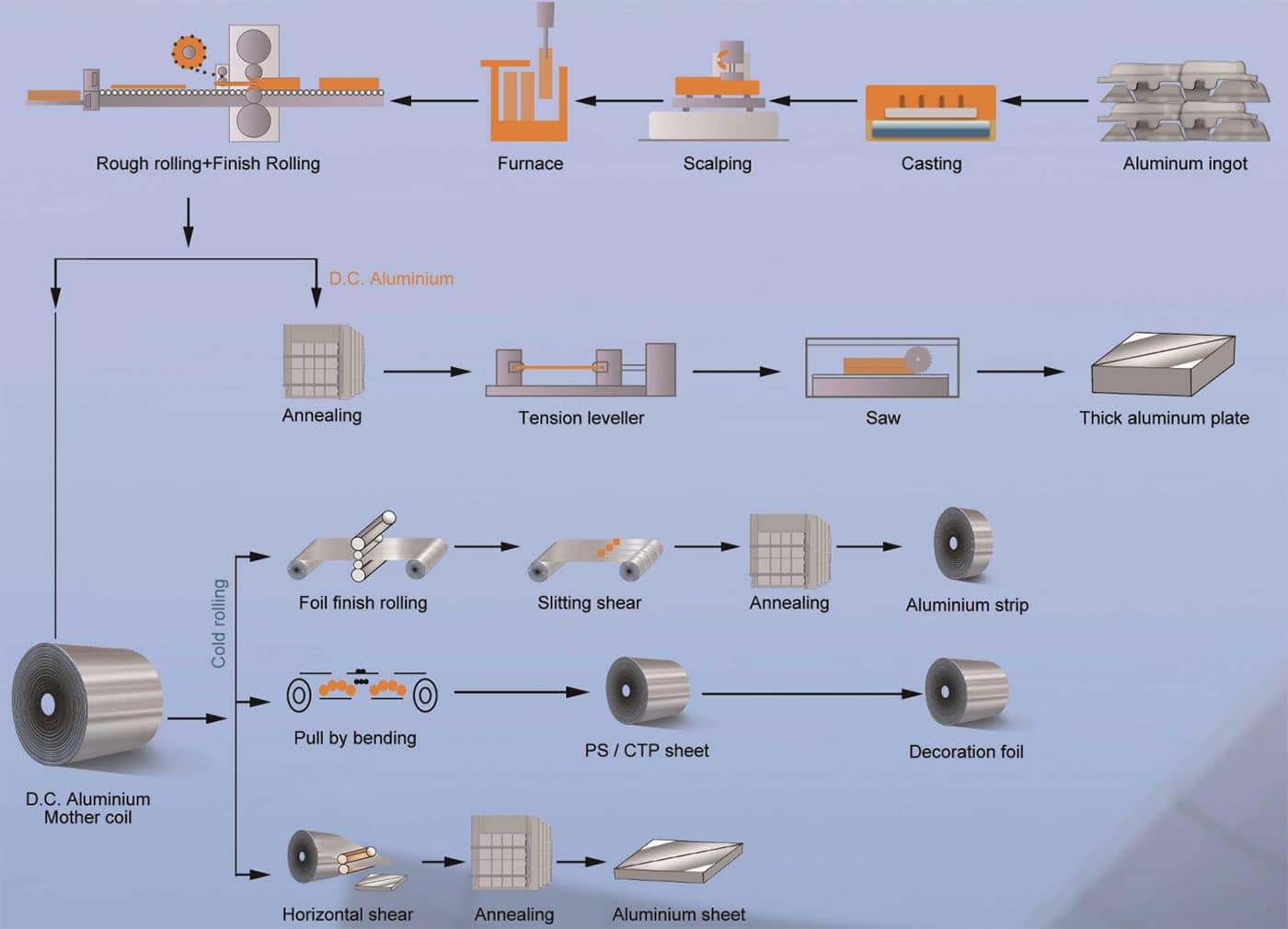

Product line:

Product Catalogue:

| Products | Alloy No. | Temper | Thickness(mm) | Width(mm) |

|---|---|---|---|---|

| 1000series | 1050/1060/1100/1235/1200/1145 | All Tempers | 0.2-6 | Under2200 |

| 3000series | 3003/3105 | All Tempers | 0.2-6 | Under2200 |

| 5000series | 5005/5052/5083/5086/5182/5754/5454/5A06/5A05/5251 | All Tempers | 0.2-6 | Under2200 |

| 6000series | 6061/6082/6063 | F/TX | 0.2-6 | Under2200 |

| 7000series | 7075/7050 | F/TX | 0.2-6 | Under2200 |

| 8000series | 8011 | All Tempers | 0.006-6 | Under2200 |

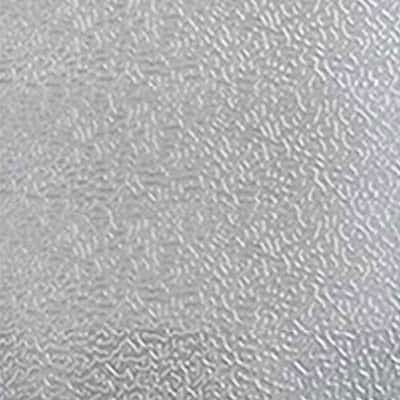

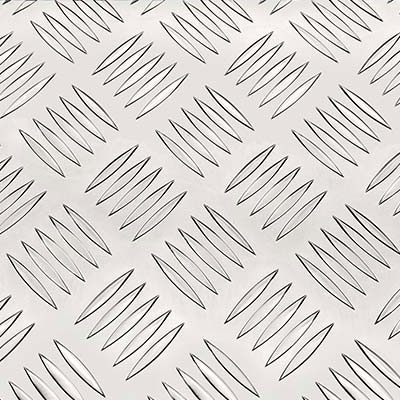

Types of Checkered Plates:

Color Coating Type:

Q: How long can I receive my goods?

A: It depends on the products you ordered. Generally, it needs 30-40 days.If products is stock , about 7-10days can delivery after received deposit.We have 3200 workers to manufacture aluminium products. We have complete production lines for meeting your needs of products quality and production speed to make sure that our products can get to you faster.

Q: What are your payment methods?

A: TT or 100% irrevocable L/C at sight.

Q: What is your MOQ?

A: Our MOQ is based on the alloy number and the thickness and width of the aluminum sheet.1000 series MOQ 5tons.

Q: How do you ship the goods and how long does it take to arrive ?

A : We usually ship by DHL , UPS , Fedex or TNT for sample. It usually takes 3-5 days to arrive . Seashipping for mass products.

Q: Are your aluminium products quality reliable?

A : We apply professional and advanced equipment for processing aluminium products. These equipment are top-class at home and abroad. What’s more, our factory has complete equipment configurations for fine machining. And we have precise equipment for testing products quality. Thus, the quality of end products can be promised.