1100 Aluminum Sheet Introduction:

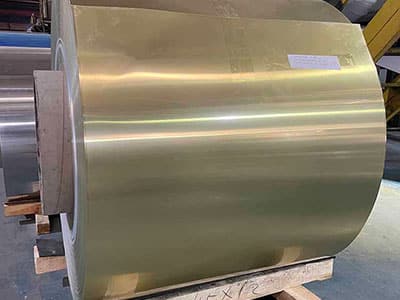

1100 aluminum sheet is part of the 1000 series of aluminum alloys, containing 99% AI, which is industrially pure aluminum and cannot be strengthened by heat treatment. 1100 aluminum sheet is one of the softest aluminum alloys and therefore is not used in high strength or high pressure applications and is usually hardened by cold working to improve its strength. 1100 aluminum sheet has the following characteristics: durability, long life, corrosion cracking resistance, formability, flexibility, heat resistance and weldability.

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al |

| Content (max) | 0.95 | 0.40 | 0.05 | 0.05 | 0.05 | – | 0.10 | – | 0.15 | 99.95 |

1100 Aluminum Sheet Feature:

Good corrosion resistance. 1100 can withstand most acidic organic corrosion in addition to the common resistance to atmospheric corrosion and water corrosion.

No low temperature brittleness. Temperature below 0℃ is, as the temperature decreases, its strength and formability will continue to increase.

Good ductility and workability. Because 1100 aluminum sheet is very soft, it is usually formed by spinning, stamping and drawing process, and can be adapted to most machine tools for turning, milling, boring, planing and other mechanical processing.

1100 Aluminum Sheet Application:

1100 aluminum sheet is widely used in various fields from cookware to industrial equipment, such as large storage tanks, radiators, lids, printing sheets, construction materials, heat exchanger components, storage tanks, food industry devices, deep-drawn, bottle caps, wide curtain walls, engine panels , decoration, heat sinks, hardware, etc.

It can also be used as deep-drawn stamping products, especially 1100-H24 aluminum sheet is widely used in car doors and bus bodies.

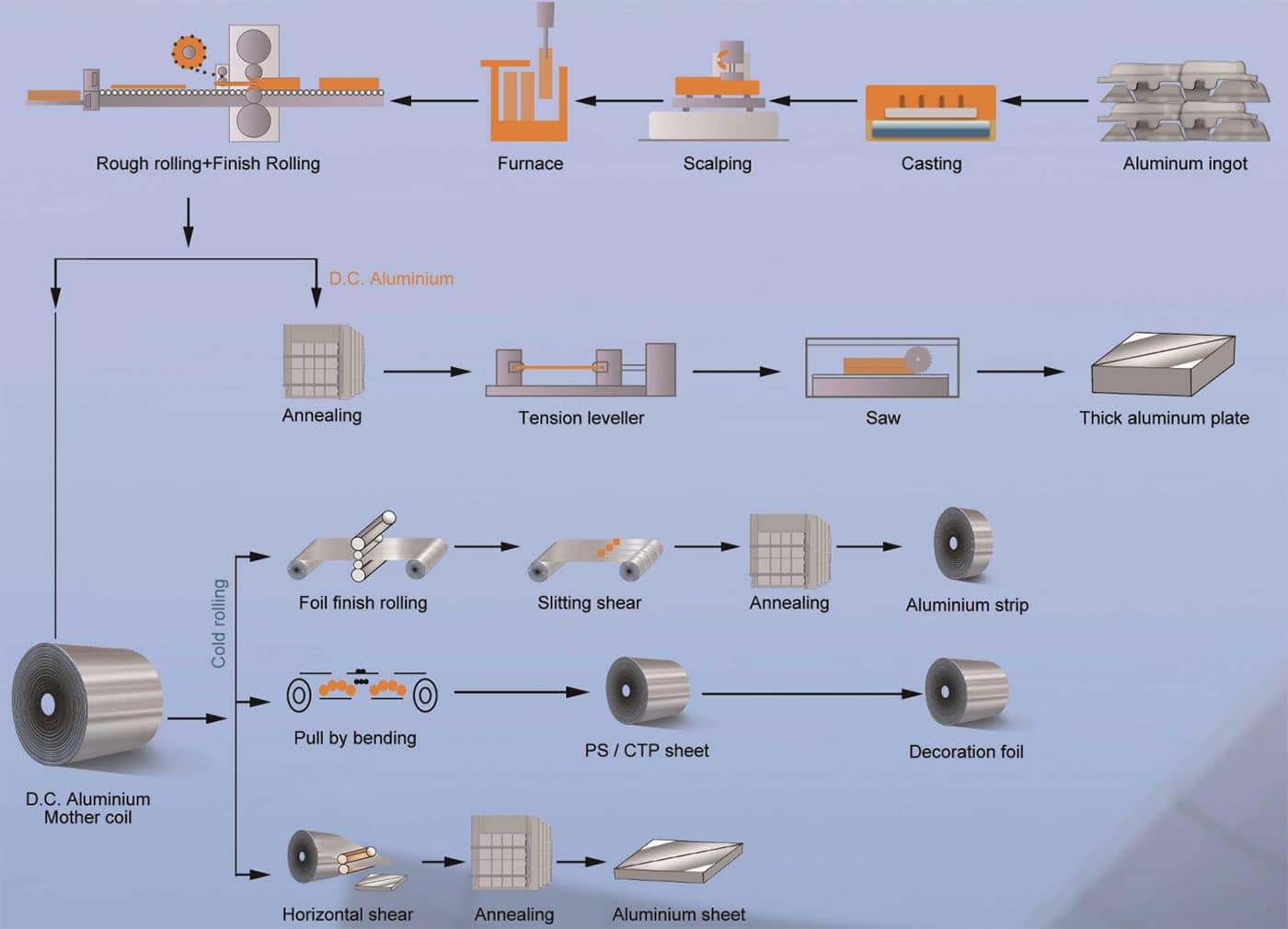

Product line:

Product Catalogue:

| Products | Alloy No. | Temper | Thickness(mm) | Width(mm) |

|---|---|---|---|---|

| 1000series | 1050/1060/1100/1235/1200/1145 | All Tempers | 0.2-300 | Under2200 |

| 3000series | 3003/3105 | All Tempers | 0.2-300 | Under2200 |

| 5000series | 5005/5052/5083/5086/5182/5754/5454/5A06/5A05/5251 | All Tempers | 0.2-300 | Under2200 |

| 6000series | 6061/6082/6063 | F/TX | 0.2-300 | Under2200 |

| 7000series | 7075/7050 | F/TX | 0.2-300 | Under2200 |

| 8000series | 8011 | All Tempers | 0.006-0.2 | Under2200 |

Types of Checkered Plates:

Color Coating Type:

1. Cover the fumigation chapter.

2. Place 20 packs of desiccant per carton.

3. Galvanized steel strip, coated cardboard package to prevent rust.

4. Pine wood bottom bracket is supported by glued bottom plate to maintain the flatness of the aluminum plate.

Q: How long can I receive my goods?

A: It depends on the products you ordered. Generally, it needs 30-40 days.If products is stock , about 7-10days can delivery after received deposit.

We have 3200 workers to manufacture aluminium products. We have complete production lines for meeting your needs of products quality and production speed to make sure that our products can get to you faster.

Q: What are your payment methods?

A: TT or 100% irrevocable L/C at sight.

Q: What is your MOQ?

A: Our MOQ is based on the alloy number and the thickness and width of the aluminum sheet.1000 series MOQ 5tons.

Q: How do you ship the goods and how long does it take to arrive ?

A : We usually ship by DHL , UPS , Fedex or TNT for sample. It usually takes 3-5 days to arrive . Seashipping for mass products.

Q: Are your aluminium products quality reliable?

A : We apply professional and advanced equipment for processing aluminium products. These equipment are top-class at home and abroad. What’s more, our factory has complete equipment configurations for fine machining. And we have precise equipment for testing products quality. Thus, the quality of end products can be promised.