5454 Aluminum Sheet Introduction:

5454 aluminum sheet and 5754 aluminum sheet are similar in basic properties, both belong to aluminum and magnesium alloy, both belong to 5000 series alloy.

5454 aluminum sheet has medium to high strength, corrosion resistance, plasticity, high fatigue strength, suitable for the marine industry. Under most extreme conditions, it can withstand high temperature and pressure, and is suitable for aluminum tanker and other fields. However, it is not suitable for complex or fine extrusion.5454 aluminum sheet has good weldability and can be easily welded in place. However, welding and brazing of the sheet is not recommended

| Chemical Composition Limits | |||||||||||

| Alloy No. | Al | Si | Fe | Cu | Mn | Cr | Ti | Mg | Zn | Others Each | Others Total |

| 5454 | Bal | 0.25 max | 0.40 max | 0.10 max | 0.50 / 1.0 | 0.05 / 0.20 | 0.20 max | 2.4 / 3.0 | 0.25 max | 0.05 max | 0.15 max |

Typical Mechanical Properties:

| Alloy No. | Temper | Thickness (mm) | Tensile Strength (N/mm²) | Yield Strength (min) (N/mm²) | Elongation in 50mm (%) | ||||

| 0.5 mm | 0.8 mm | 1.3 mm | 2.6 mm | 3.0 mm | |||||

| 5454 Aluminium Sheet | 0 | 0.2-6.0 | 215-285 | 80 | 12 | 14 | 16 | 18 | 14 |

| 5454 Aluminium Sheet | H22 | 0.2-3.0 | 250-305 | 180 | 4 | 5 | 7 | 8 | – |

| 5454 Aluminium Sheet | H24 | 0.2-3.0 | 270-325 | 200 | 3 | 4 | 5 | 6 | – |

5454 Aluminum Sheet Features:

Since 5454 aluminum sheet has less hard and brittle compounds, it is not easy to produce processing cracks.

5454 aluminum plate has good corrosion resistance and high tensile strength. Aluminum alloy has a corrosion resistance that is incomparable to steel.

Aluminum tanker plate has good electrical conductivity and energy absorption properties. Collision with other vehicles will not produce sparks, thereby reducing the occurrence of accidents such as explosions

5454 Aluminum Sheet Application:

The application of 5454 alloy aluminum plate is usually used for:

~ Road Transport Body Manufacturing

~ chemical plant

~ Pressure Vessels, Vessels, Boilers

~ Offshore Industry

~ Towers, poles and masts

~Welded structure

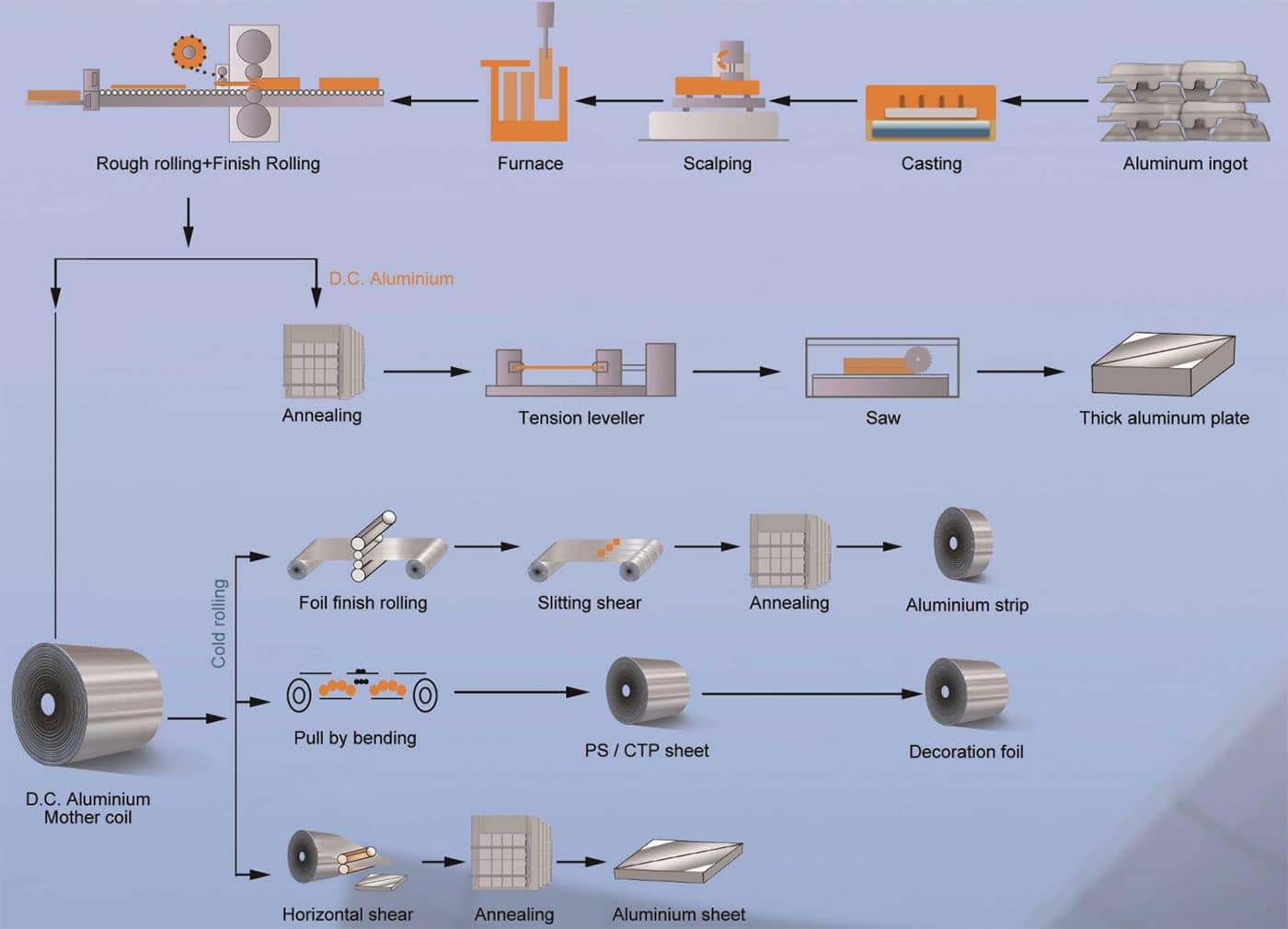

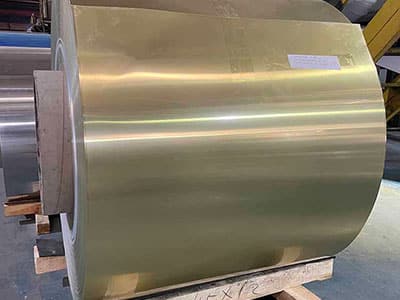

Product line:

Product Catalogue:

| Products | Alloy No. | Temper | Thickness(mm) | Width(mm) |

|---|---|---|---|---|

| 1000series | 1050/1060/1100/1235/1200/1145 | All Tempers | 0.2-300 | Under2200 |

| 3000series | 3003/3105 | All Tempers | 0.2-300 | Under2200 |

| 5000series | 5005/5052/5083/5086/5182/5754/5454/5A06/5A05/5251 | All Tempers | 0.2-300 | Under2200 |

| 6000series | 6061/6082/6063 | F/TX | 0.2-300 | Under2200 |

| 7000series | 7075/7050 | F/TX | 0.2-300 | Under2200 |

| 8000series | 8011 | All Tempers | 0.006-0.2 | Under2200 |

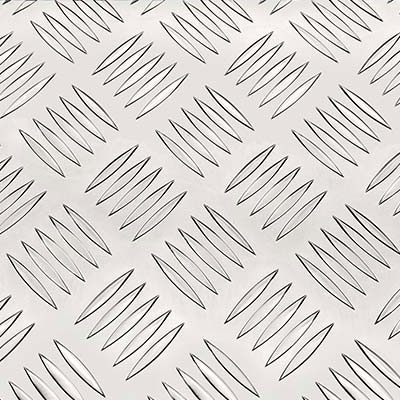

Types of Checkered Plates:

Color Coating Type:

1. Cover the fumigation chapter.

2. Place 20 packs of desiccant per carton.

3. Galvanized steel strip, coated cardboard package to prevent rust.

4. Pine wood bottom bracket is supported by glued bottom plate to maintain the flatness of the aluminum plate.

Q: How long can I receive my goods?

A: It depends on the products you ordered. Generally, it needs 30-40 days.If products is stock , about 7-10days can delivery after received deposit.

We have 3200 workers to manufacture aluminium products. We have complete production lines for meeting your needs of products quality and production speed to make sure that our products can get to you faster.

Q: What are your payment methods?

A: TT or 100% irrevocable L/C at sight.

Q:What is your MOQ?

A: Our MOQ is based on the alloy number and the thickness and width of the aluminum sheet.1000 series MOQ 5tons.

Q4 . How do you ship the goods and how long does it take to arrive ?

A : We usually ship by DHL , UPS , Fedex or TNT for sample. It usually takes 3-5 days to arrive . Seashipping for mass products.

Q: Are your aluminium products quality reliable?

A : We apply professional and advanced equipment for processing aluminium products. These equipment are top-class at home and abroad. What’s more, our factory has complete equipment configurations for fine machining. And we have precise equipment for testing products quality. Thus, the quality of end products can be promised.